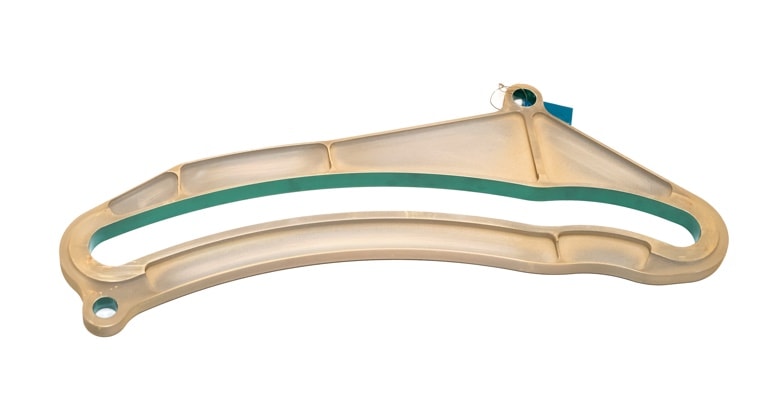

Here’s where we really shine. Our plating department boasts 12,000 square feet of dedicated space, 75 plating tanks, 4 ovens and some of the most experienced plating specialists in the industry.

The plating department at All Metals is housed in a 12,000 square foot building and has consistently provided the highest quality of expertise in the industry, with seasoned plating specialists with over four decades of experience. This building maintains 75 plating tanks and four ovens to keep up with our customers plating demands. Our plating department has collaborated with many prime contractors to develop special processes to meet a specific need. The department’s capabilities range from titanium cadmium plating to precious metal plating such as silver. Our quality in this department is unmatched in the metal finishing industry.

Thin but mighty, cadmium plating is widely used and appreciated for its compatibility with aluminum and steel and its ability to resist corrosion, even in extreme environments. Additional benefits of cad plating include strength, malleability, lubricity, solderability and softness—all while serving as a great base for primer and paint.

+View details

Titanium Cadmium plating is a specialized process for that improves the corrosion resistance of cadmium plating alone and significantly reduces the effect of hydrogen embrittlement. All Metals produces one of only 3 Boeing approved Titanium Pastes (Ti-Plate 504).

+View details

Electroless nickel plating is used to apply uniform, precision coatings to ID and OD surfaces of complex shapes. It is applied with phosphorous coatings to offer superior corrosion resistance, hardness and wear resistance. It is used for applications such as shafts, piping, ducts, molds, dyes, enclosures, bores and processing equipment.

+View details

All Metals provides Copper plating services, essential in many plating operations as a strike and for thick deposits. It can also be applied as an undercoat or strike between substrates and a final deposit to cover defects such as holes and splinters. When used as an undercoat, copper plating also

+View details

Tin plating is a common, electrolytic plating process. By applying a coating of tin to the substrate, the part acquires a conductive and solderable finish. Tin plating is often used in the aerospace industry to protect items made from base metals like copper, nickel and other non-ferrous metals.

+View details

Like copper plating and tin plating, silver plating is an electrolytic plating process used to create a layer of protection to a base metal. An electrical current is used to deposit silver onto a substrate. The coating alters the surface properties to improve conductivity and solderability. Silver plating is very

+View details

Electropolish, or electrolytic polishing, is a pretreatment process. It uses electricity and chemistry to remove a small amount of material from a stainless steel surface, thereby exposing more chromium and making a shinier, more passive surface.

+View details